Call 08006546537 to arrange your site assessment

Our process: How Resin Bound London works

We believe a great finish starts with good groundwork, and great communication. That’s why our resin installation process is transparent, hands-on, and designed to give you confidence every step of the way. Here’s exactly how we work:

- 1Initial site assessment Every job starts with a visit. During our first meeting, we will measure up the area, check drainage and current surface conditions, assess the sub-base for stability and suitability. We’ll also bring samples so you can choose your colour in natural light and explore all design options available.

- 2Pre-installation preparation When we arrive for installation, we ask that you clear what you can from the area. We’ll handle the rest. We’ll move large pots or furniture, protect surrounding surfaces and minimise disruption. Our goal is to make your experience smooth, tidy, and stress-free.

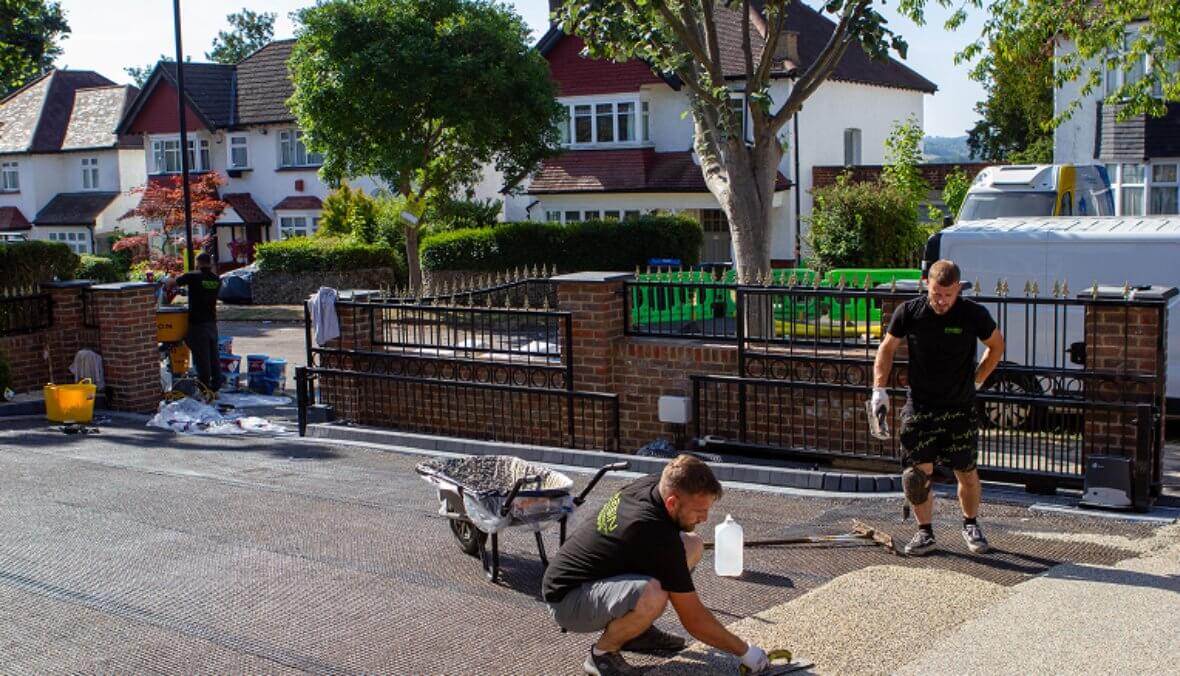

- 3Base preparation Proper preparation is critical for a durable finish. And that is why we carry out excavation if the existing surface is not suitable and levelling to create a stable, even foundation. We ensure all basework is done to industry standards to make it ready for resin application.

- 4Edging installation Edges are where most surfaces fail. We install edging restraints that reinforce the perimeter of your surface, define the shape and design and helps maintain the integrity of your finish over time. This might be with metal edging, block borders, or other materials based on your design.

Reviews

Ready to start?

We’re here to guide you from quote to completion, and long after. You can get in touch with us by calling 08006546537 or emailing [email protected].

Surface cleaning and resin mixing

Before any resin is laid, we thoroughly clean the base to remove dust, debris and moisture. We then mix the resin bound system in small, controlled batches. This part is time-critical because once mixed, the resin has a working time (“pot life”) of 30 minutes or less, temperature and humidity affect how quickly it sets. This process is where experience truly counts.

Laying the resin surface

We apply the resin bound surfacing to your prepared base with precision and care. Mixed aggregate is poured and spread evenly and then trowelled by hand for a smooth. We only use premium materials from suppliers like Vuba and the latest tools to guarantee a consistent and professional result.

Curing and access time

Once the resin surface is laid, it needs time to cure before it can be safely used. Light foot traffic is generally fine after around 3 to 4 hours, but for vehicles, we recommend waiting approximately 48 hours. This ensures the surface has properly set and can handle the weight without damage. We’ll clearly let you know when it’s safe to walk or drive on your new surface, no need to guess.

Final inspection and clean-up

After the resin has cured, we carry out a final inspection to check the surface for consistency and finish. We also clean the site thoroughly, so everything looks neat and tidy. At this stage, we’ll talk you through aftercare and maintenance to help keep your surface looking great for years to come. If we moved any furniture or heavy items during the process, we’re happy to return after a few days to put them back in place. We take pride in every project we complete, and we’re not done until you’re 100% happy.

Still have questions?

We understand that choosing the right surface for your home or business is a big decision. That’s why we’re happy to answer any queries you might have about the process, materials, or options available. You can either call us on 08006546537 or emailing [email protected].